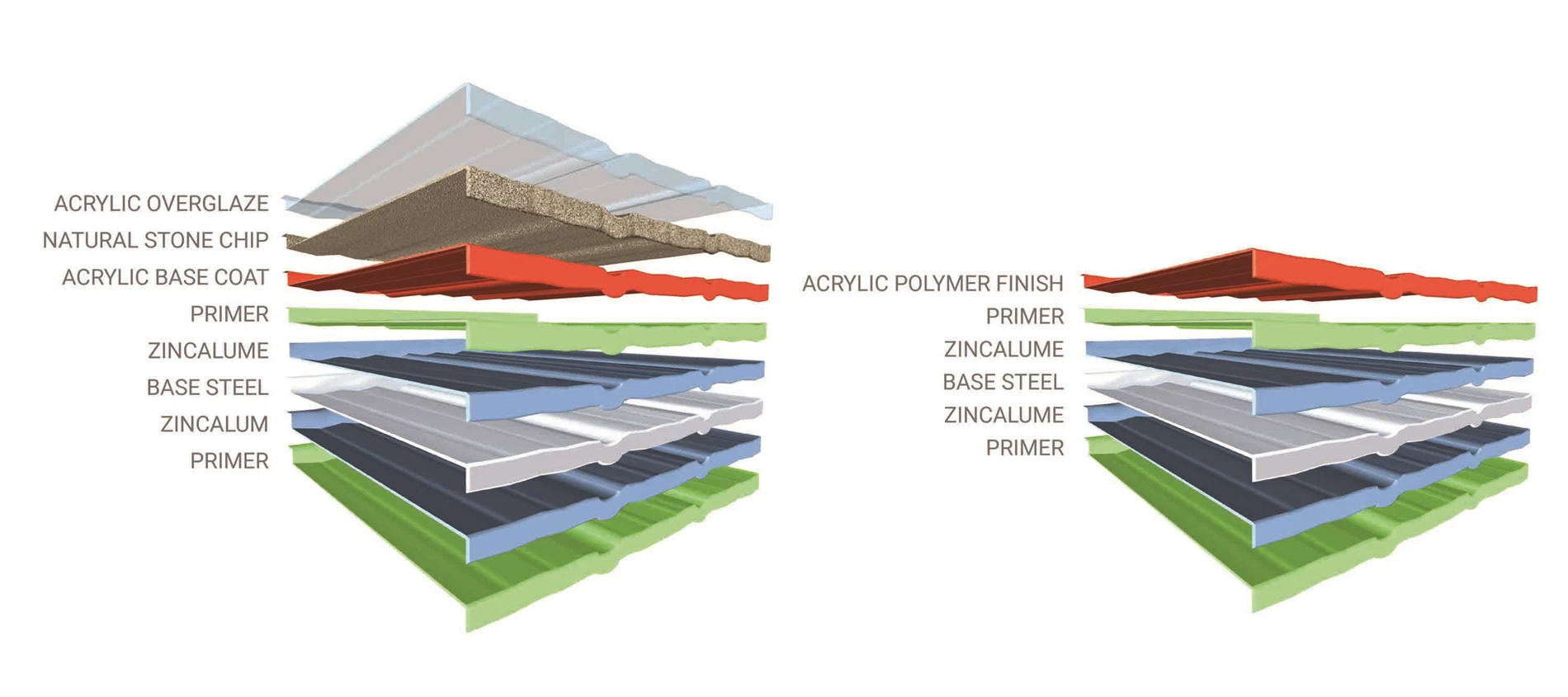

DECRA stone coated steel roof tile is made from aluminium-zinc coated steel (Grade G300 & AZ 150), conforms to AS 1397:2001 standard that provides superior corrosion resistance performance and coated with acrylic basecoat, natural/ceramic coated volcanic stone chips and acrylic overglaze.

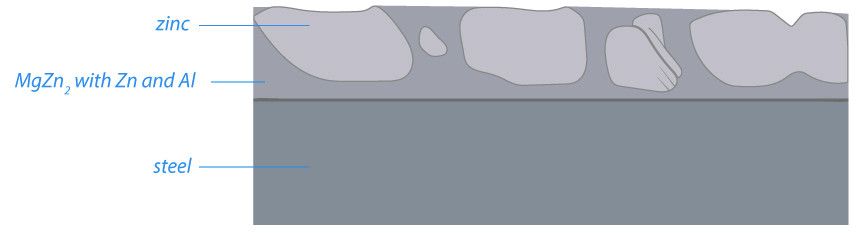

The AZ150 steel is the heart of the Decra® tile and provides it with its strength, rigidity, and lightweight. Decra® tiles are made with strong AZ150 steel, which is special because it’s protected on both sides with aluminum-zinc alloy. That double layer of protection makes the tiles resistant to any physical damage and provides excellent protection against weather conditions. The unique alloy composition of AZ150 with optimal balance between zinc, aluminium and silicon, provides superior corrosion resistance by combining the sacrificial protection of zinc with the barrier protection of aluminum and silicon.

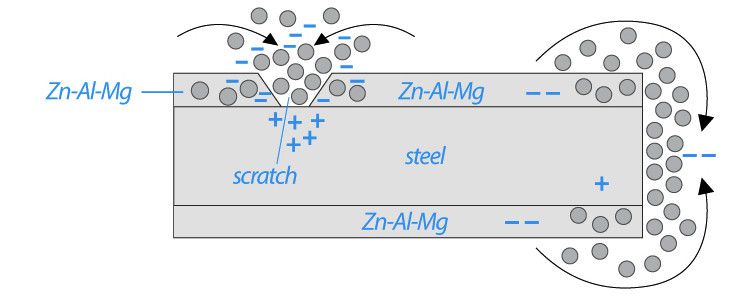

The primary protection for the steel is a coating of aluminium-zinc applied by passing the cleaned steel through a bath of molten aluminium-zinc, to metal coat it. The aluminium-zinc coating combines the oxidation layer corrosion protection of aluminium with the sacrificial protection of zinc, giving the protective advantages of both metals. A significant benefit of the zinc component is that it even protects areas of steel not completely covered, such as cut edges, drilled holes, scratches and others.

The APS Coating is applied to both sides of the aluminium-zinc. This is a 1 to 2 micron film of acrylic that has been tinted. The APS coating is applied by rollers immediately after the application of the aluminium-zinc coatings. It provides a uniform substrate that enhances adhesion of subsequent topcoats (basecoat and paint). The tint provides proof that a coating has been applied and the clarity allows identification of the characteristic very low spangle appearance of the aluminium-zinc coating.

The stone chips are bonded to the tile by means of the basecoat. Made in two colours – brown and black – to tone in with the various chip colours, this is a specially formulated high-build paint, based on a custom designed 100% acrylic resin binder. The basecoat serves two functions. The first is to bond the chips which form the decorative layer, onto the tile. The second is to protect the underlying layer from water and UV radiation. The ability to bond the chips is given by he thickness of the coating and its adhesion to chip. A properly applied and dried basecoat should resist complete penetration by water after total immersion for periods in excess of 24 hours.

Basecoat is formulated to have good durability so as to retain its adhesive properties for the life of the tile. It has good UV resistance and retains its flexibility although it does become harder after the first few weeks. While this tough adhesive coating retains the chip well, it also protects the APS coating on the steel from UV and weather.

Basecoat alone, however is not very attractive in appearance, so to provide an attractive textured finish and at the same time enhance resistance to UV radiation, a layer of stone chip is applied to the tiles. A range of colours made from rocks selected for durability to water, UV and acid rain, provide both an attractive appearance, and protection of the basecoat. The chip is sized and applied in such a way as to ensure virtually 100% cover of the basecoat, and this total and even coverage is a feature carefully watched by inspectors and operators.

Where other colours are required than the limited range of natural colours, the same durable natural rock is ceramic coated using heat resistant and UV stable pigments. Samples have shown over 20 years exposure life without colour change. This coating process is now carried out by DECRA at its own premises to ensure consistency and quality

The stone chips are bonded to the tile by means of the basecoat. It serves two main purposes: first, to bond the stone chips, which form the decorative layer, onto the tile and secondly, to protect the underlying layer from water and UV radiation. It has also good UV resistance and retains its flexibility although it does become harder after the first few weeks

To provide this attractive textured finish and at the same time enhance resistance to UV radiation, a layer of carefully selected stone granules is applied to the tiles. The granules are either volcanic, for naturally occurring colors that will not fade or ceramic coated stone chips with lightfast heat resistant pigments. They both prevent discoloration from the sun’s rays, ensuring that you will not have a faded roof after years from installation.

While the chip has an attractive colour range, it is virtually all matt in appearance. In addition, while the chip is well bonded to the tile by the basecoat, the latter continues to harden for up to six months after manufacture. The acrylic overglaze applied at the final coat to the tile improves both these factors. The tough, thin film flows between the chips into the basecoat, and dries to give a clear “water wet” gloss to the chip. It thus bonds the chip thoroughly to the basecoat leaving it virtually encapsulated by an acrylic film, which enhances the appearance as well as increasing the resistance to physical damage.

In DECRA’s manufacturing process, the tiles are pressed first before the textured coating is applied and then baked, which contributes significantly to the durability of the tiles coating.